ZJK Industrial Co., Ltd. Triples Captive Screw Production Efficiency with New Semi-Automatic Equipment

Traditionally, the production of captive screws involves assembling multiple components and manual punching, leading to low efficiency and inconsistent quality. Captive screws are composed of screws, housings, and springs, and require specialized tooling to prevent parts from dislodging before stamping and assembly. Additionally, the stamping mechanism’s working pressure must be adjusted to accommodate products of varying specifications. These challenges contribute to high manufacturing complexity and cost, despite the strong market demand for such fasteners.

To address these issues, ZJK invested in research and development to design a semi-automatic assembly system. The new system incorporates a circular workbench with a divider and an adjustable stamping mechanism, allowing seamless integration into automated assembly lines without manual intervention.

With this new equipment now operational, the Company has significantly enhanced its existing automated assembly capabilities for combined parts and opened up new possibilities for subsequent assembly processes. According to the Company, the new system has increased captive screw production efficiency by over three times and reduced required labor by 50%, further strengthening ZJK’s competitive edge in the fastener sector.

Learn More

Related News

ZJK Industrial Co., Ltd. Reports Financial Results for the First Six Months of Fiscal Year 2025

ZJK today announced its unaudited financial results for the first six months of fiscal year 2025 ended June 30, 2025.

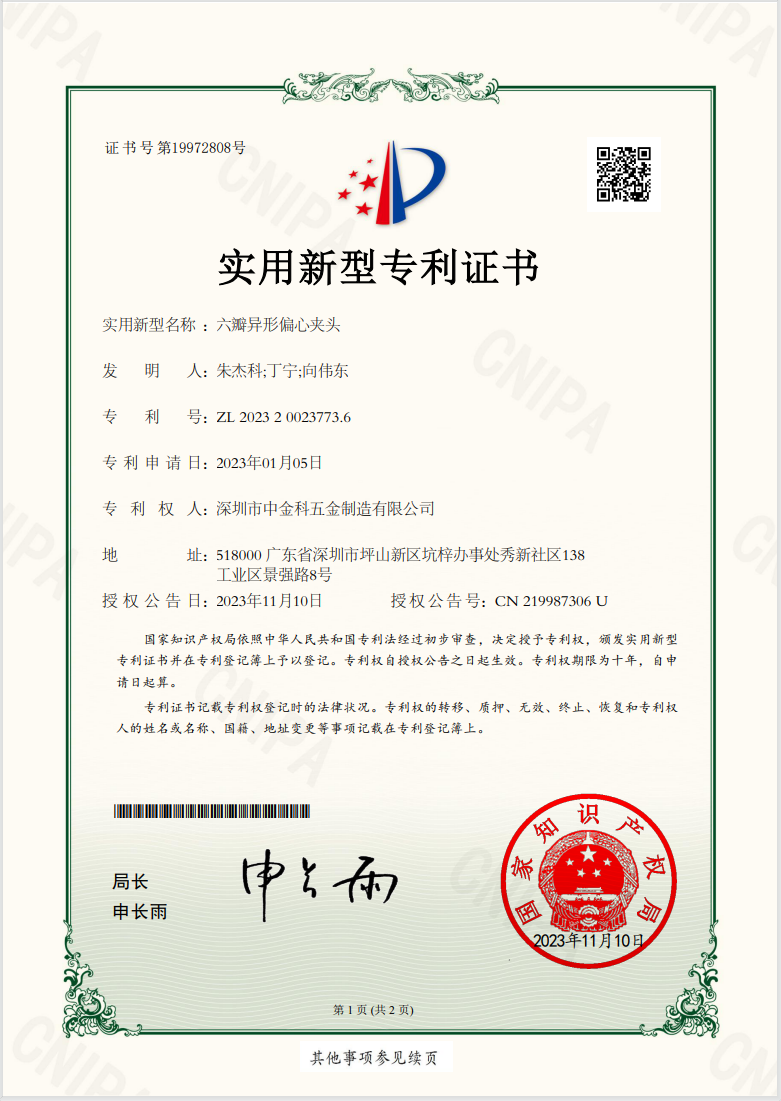

ZJK Industrial Boosts Production Efficiency for AI Servers and Robotics components with Patented Six-Flap Eccentric Chuck

ZJK announced the integration of a six-flap eccentric chuck into its production line for machining irregularly shaped, eccentric, and thin-walled workpieces. This advanced chuck significantly improves production efficiency, reduces the risk of workpiece deformation, and minimizes reliance on operator alignment skills.

ZJK Industrial Co., Ltd. Triples Captive Screw Production Efficiency with New Semi-Automatic Equipment

ZJK announced the deployment of newly developed semi-automatic punching equipment for captive screws production. This advanced equipment significantly enhances automation in captive screw assembly, increasing production efficiency by more than threefold and reducing manual labor and related costs.